Kilowatt boost for USP material processing

A new ultrashort pulse (USP) laser beam source from TRUMPF, designed for industrial use, will expand the range of applications of USP laser processes. The Fraunhofer Institute for Laser Technology ILT in Aachen will be systematically exploring the potential of this beam source with an average output of 1 kW in the coming months. Among other things, experiments are planned to optimise processes in battery and fuel cell production, toolmaking and semiconductor technology, as well as to test various beam guidance strategies. Many of these pilot applications originate in the Fraunhofer internal Cluster of Excellence Advanced Photon Sources (CAPS).

“In the Fraunhofer CAPS cluster, we want to clarify how high-power beam sources can expand the range of applications for USP laser processes,” explains Dr. Dennis Haasler, leader of the group Micro- and Nano Structuring at Fraunhofer ILT. His team will systematically explore this question over the next few months using appropriate experiments. The focus will be on a new USP laser beam source from TRUMPF with an average output power of 1 kW.

As part of a bilateral cooperation, the company is providing the new TruMicro 9000. “For the first time, we have a kilowatt beam source that performs like established industrial USP lasers in the 200 W class,” explains Haasler. He and his team will now evaluate how the high-energy laser pulses can be used for industrial manufacturing and finishing processes.

High performance based on combination of proven technology components

“By combining tried-and-tested technology components in the amplifier chain, we have succeeded in significantly increasing both the maximum individual pulse energy and the resulting average power,” reports Steffen Rübling, product manager for the USP lasers in the TruMicro family at TRUMPF.

In addition to this technological diversity within their portfolio, the team also benefited from the knowledge gained from component development for continuous wave (cw) and short pulse lasers. For example, the main amplifier of the new TruMicro 9000 – a so-called multi-pass cell – was originally used to amplify nanosecond pulses in the power range of 3 kW.

Process strategies

The ILT team will focus on process control strategies and system designs that can be used to optimally utilise the high average power for processing the respective workpieces. Several test setups are available in the Fraunhofer ILT laboratory for this purpose, which the team can use to direct the high power and energy input of the beam source onto the component surfaces for effective and gentle processing. A key advantage of USP laser processes comes into play here: Although their femtosecond or picosecond pulses concentrate a great deal of energy, the thermal load on the material remains minimal thanks to their short duration.

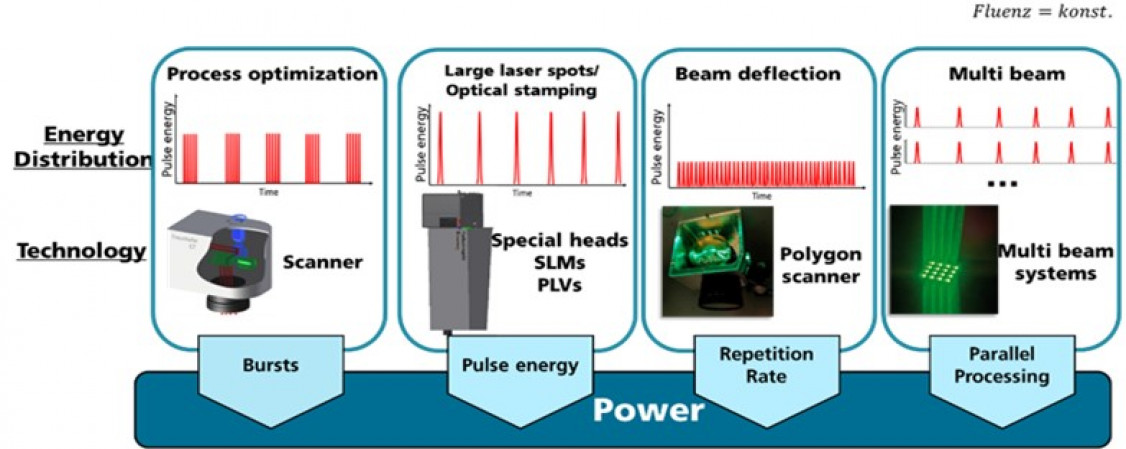

As the new system has a power level of 1 kW and high pulse energy, beam splitting and beam guiding strategies that promise increased productivity through the parallelisation of the machining processes are necessary. To prove this, Haasler's team will be relying on the four system technology approaches shown schematically in the chart: The simplest approach is the burst mode that can be implemented with conventional galvo scanners. Here, the high energy of the femtosecond pulses is distributed over up to eight individual pulses. The researchers will also be using special system technology and optical strategies for beam shaping and ultrafast beam deflection or for the parallelization of machining processes. “We need the different approaches in order to find out which strategy we can use to achieve the highest productivity for the respective industrial application,” explains Haasler. For example, a different system technology is required for the selective ablation of polymer layers from compound bipolar plates than for the point-by-point removal of active material layers on battery electrodes for their contacting or for the micro structuring of metal surfaces.

Ultrafast beam guiding or splitting into up to 900 individual beams

At Fraunhofer ILT, the team will combine the new kilowatt beam source with a polygon scanner from Moewe, which enables scanning speeds of up to 1 km/s on a processing area of 700 × 900 mm². A multi-beam system is also available for the tests, which allows testing various processing strategies with a single beam or beam splitting into 100 or even up to 900 parallelised partial beams on a processing area of 400 x 400 mm². The fourth option available is beam shaping with spatial light modulators (SLM). This promising approach is currently still under development. As the beam can be transformed into optical stamps of almost any design, it could ensure even greater processing efficiency in the future. “This is especially true in combination with high-power USP lasers,” says Haasler.

Fraunhofer ILT will now systematically clarify how the power and pulse energy of the new USP beam source can be utilised to benefit production with the respective beam guidance and process strategies. The pilot applications come from practical experience. Input is provided by the CAPS cluster, which includes 21 Fraunhofer Institutes. Within the cluster, they can access the specific laser expertise of Fraunhofer ILT and the two Fraunhofer Institutes for Applied Optics and Precision Engineering IOF in Jena and for Material and Beam Technology IWS in Dresden for their own project ideas and applications for their industrial partners. Other USP applications evaluated by the team have their origins in various collaborative research projects in which Fraunhofer ILT is working with industrial partners to find new process solutions for the production of batteries, fuel cells or electrolyzers. In addition, there are many applications in toolmaking, medical and environmental technology, semiconductor production and printed electronics in which USP material processing promises quality advantages.

Demand for USP processes

The Fraunhofer team will now clarify in detail how the kilowatt power can be used in material processing and how the high power level affects the process quality, the workpieces and the optics used. “Ten millijoules of pulse energy require high-quality, precisely designed optical components", explains Haasler. Practical issues such as the heat input into the component or the possible development of contamination as a result of the increased material ablation also need to be clarified. It is also unclear to what extent the combination of high ablation and repetition rates can lead to unwanted shielding of the laser beam at certain points or whether there is a risk of interaction between the ablated material and the surrounding partial beams during multi-beam processing. Other questions concern the service life and contamination of the optical elements in the process chamber and radiation protection. Last but not least, there is the question of whether 1 kW is enough or whether even more powerful lasers are needed to fully exploit the industrial potential of USP processes. According to TRUMPF Product Manager Rübling, the modular architecture of the TruMicro 9000 makes this possible: “In addition to further increasing the average power, we are also able to convert the wavelength or extend or reduce the pulse duration,” he explains.

In preparation for the tests with the current system, Fraunhofer ILT has theoretically approached various applications in micro- and nano structuring and calculated the required laser power based on the required material ablation volumes and rates. The spectrum of these applications includes the targeted structuring of graphite layers on the electrodes of lithium-ion batteries to increase their power density and fast-charging capability, the selective ablation or selective roughening of bipolar plates for fuel cells and electrolyzers, the laser structuring of printing rollers and specific applications in printed electronics. Other promising fields of application include ultra-fast nano-polishing, micro-drilling in water filters and cutting wafers into individual chips. According to Haasler, high-performance USP processes also hold great potential for a specific surface functionalization, for example with regard to anti-reflective properties or self-cleaning effects or friction minimization and flow optimization. The aerospace industry also has a need for such functionalization, one that the new system can fulfil since USP processes are suitable for producing highly emissive aluminum surfaces for heat dissipation from satellites.

USP lasers fuel the development of secondary sources

“The quality of USP processes has already been proven in many of the mentioned applications. The important thing now is to increase productivity to industrial levels,” explains Haasler. In order for high-performance USP processes to actually be able to improve more and more products in the future, they would have to meet the cycle times of existing process chains and the cost framework.

Another possible application is the use for secondary sources for generating X-rays, which Fraunhofer ILT is exploring together with TRUMPF and other industrial partners in the current BMBF-funded research project XProLas. USP lasers serve as an upstream beam source when generating X-rays. Their high-intensity pulses are compressed to less than 50 femtoseconds and hit the so-called target – a metal such as gallium, indium or tin – sharply focused. Depending on the respective target, different plasmas are created that emit part of their energy as extremely short-wave light. The project plans to develop highly compact, excellent X-ray sources that will provide insights into ongoing battery charging and discharging processes in the future.

Stimulating sustainability

Based on theoretical assumptions for a wide range of applications and materials the team will now begin practical trials. Their goal is to verify the assumed productivity benefits. Whether selectively ablating the polymer layers of compound bipolar plates or roughening the stainless steel surfaces of metallic bipolar plates, they will systematically examine the potential of the new 1 kW beam source. Wherever surface enlargement and modifications, polishing, the exposure of contacting zones or nano and micro structuring are required, USP processes can demonstrate their specific advantages in conjunction with the corresponding beam splitting and beam guidance strategies. Their potential ranges from significantly more productive material processing to the substitution of a wide range of chemical processes.

(Source: Fraunhofer ILT Press Release)

Schlagworte

BatteryFuel CellsLaserSemiconductorsToolsUSP