forceTig® – Automated TIG Welding with Increased Welding Speed

EWM continuously develops innovative welding processes with the goal of increasing added value for the customer. forceTig® is one of these innovative welding processes, used for automated TIG welding with increased welding speed and simple handling.

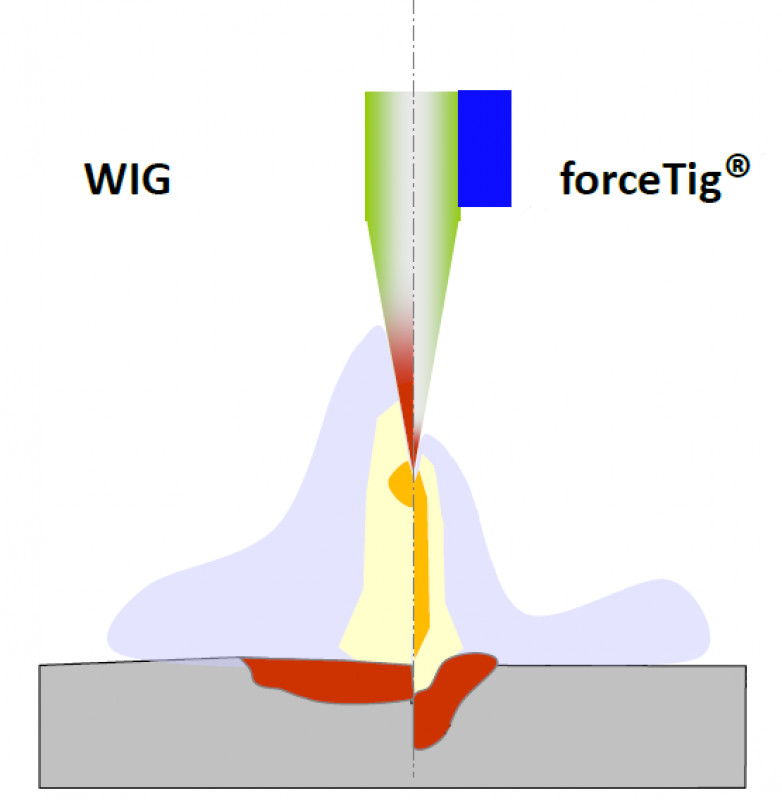

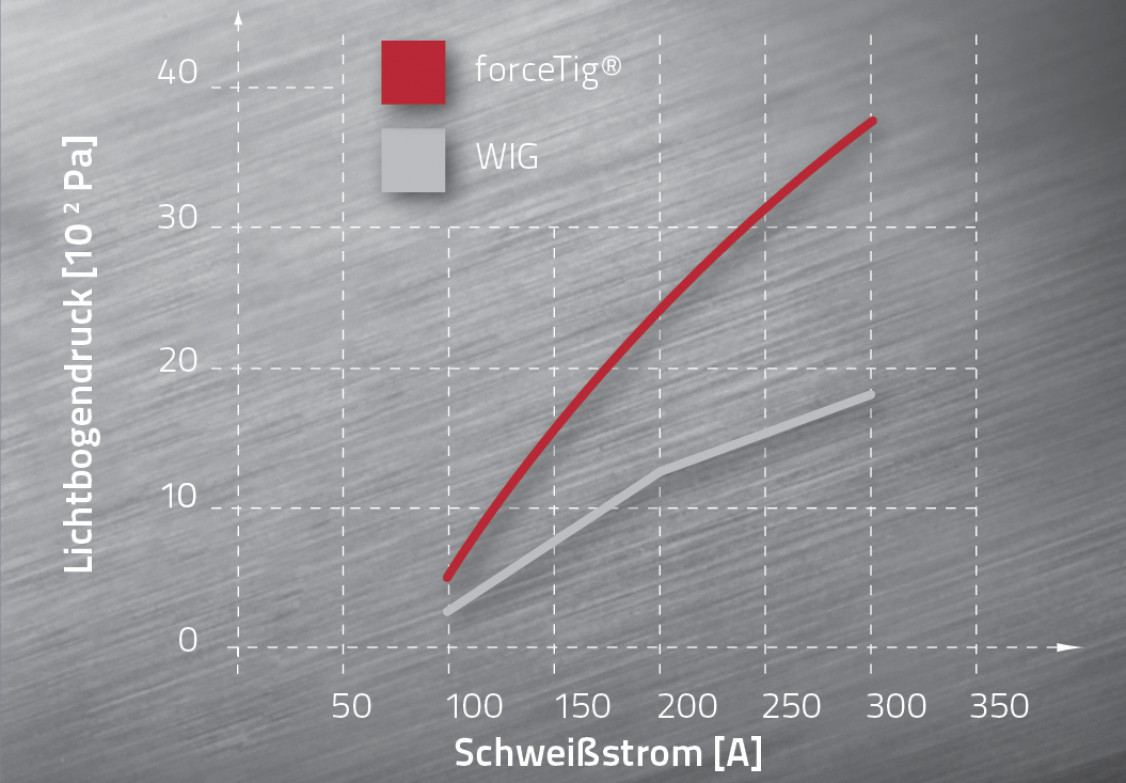

The forceTig® process – the concentrated TIG arc

forceTig® effectively constricts the arc in comparison to conventional TIG welding. The arc energy is focussed on a smaller surface. This concentration of energy increases the arc force, meaning greater energy density. This allows users to weld thin CrNi, nickel-based or titanium sheet metal at high speed. It also allows welders to weld thick metal up to ten millimetres in thickness in a single pass without weld seam preparation. PA and PC positions can be used for both welding scenarios.

The forceTig® system – optimised for automated TIG welding

The modular forceTig® system includes the power source with recooling unit, the innovative forceTig® welding torch system, a cold or hot wire feeder and all the required interfaces for automatic operation. Each individual component is perfectly tailored to one another and compatible with all market-standard mechanisation and automation components.

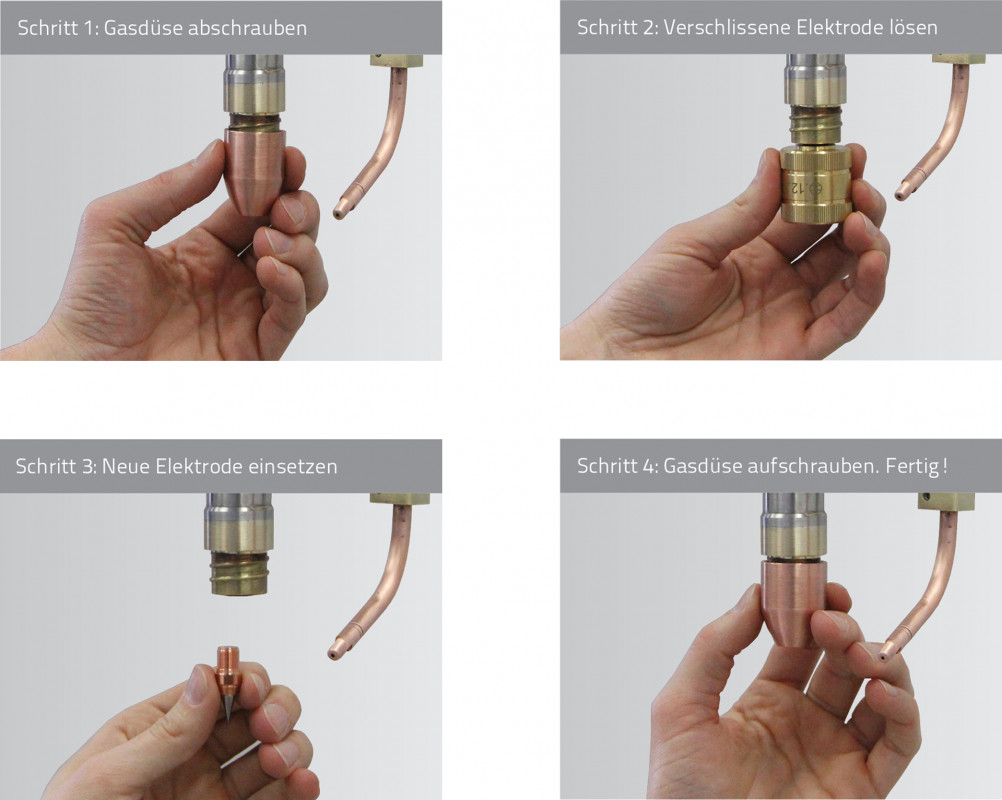

Easily replace the electrode – and continue welding

The forceTig® welding torches are optimised for automatic welding and are incredibly easy to handle. For the FT1000, welders can change electrodes extremely quickly and safely in just four steps: simply unscrew the gas nozzle, remove the worn electrode, screw in the new electrode and reattach the gas nozzle. Done. The electrode and gas nozzle are the only consumables in the welding torch system. As the electrode is calibrated, even inexperienced users can replace the electrodes safely and consistently. No separate setting gauge. The distance between the tungsten electrode tip and the component does not change once the electrode is replaced, meaning the welding results stay the same. The FT1002 offers users the advantages of a conventional TIG welding torch with its adjustable tungsten electrode, making it perfect for roots and extra thick metal plates. The water-cooled gas nozzle ensures a long service life in heavy operation. All welding torches are incredibly crash-resistant thanks to their sturdy design.

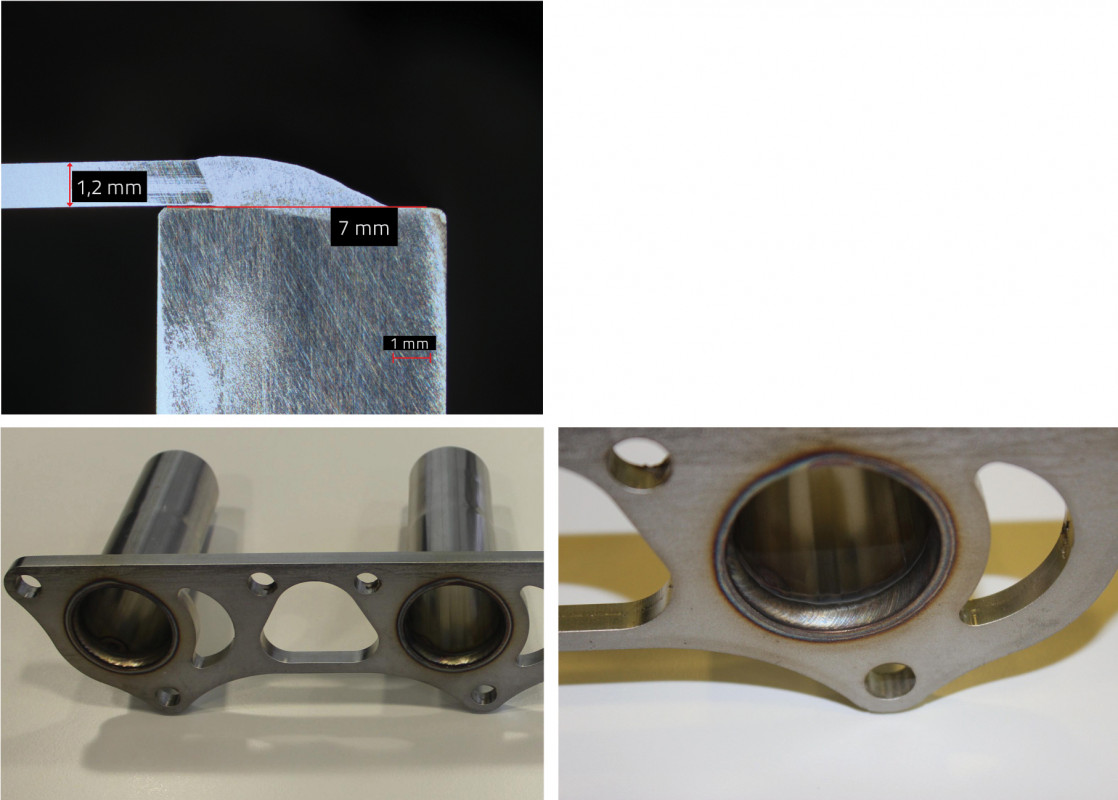

Example of use 1: Tube-flange connection – connecting metal plates with heavily contrasting thicknesses

Tube-flange connections come in all kinds of variants. Most tube-flange connections involve combining two different plate thicknesses together. The energy input is crucial here: the arc must melt the thick flange without scattering too wide, all while the thin-walled material should only lightly melt. The filler material combines these two weld pools together. Targeting heat input this way is a breeze with a highly focussed arc like forceTig®. forceTig® also perfectly masters tricky weld geometries in positional welding thanks to the incredibly directionally stable arc. This ensures reproducibility and production safety.

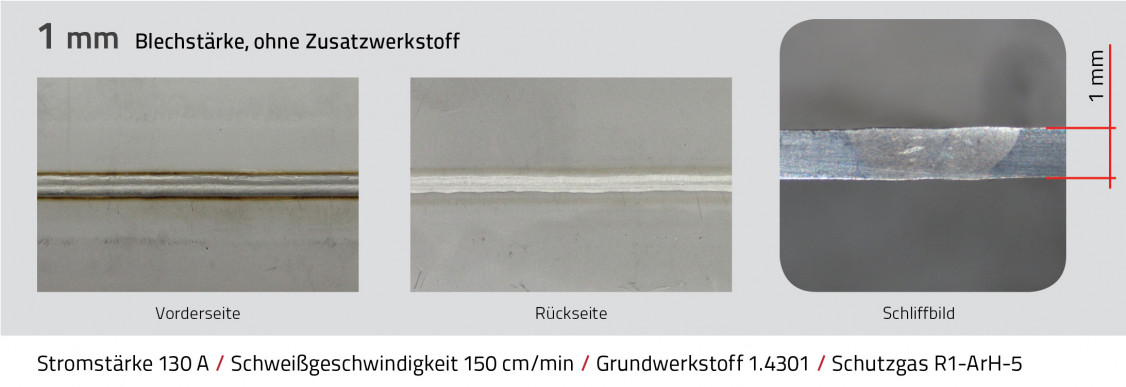

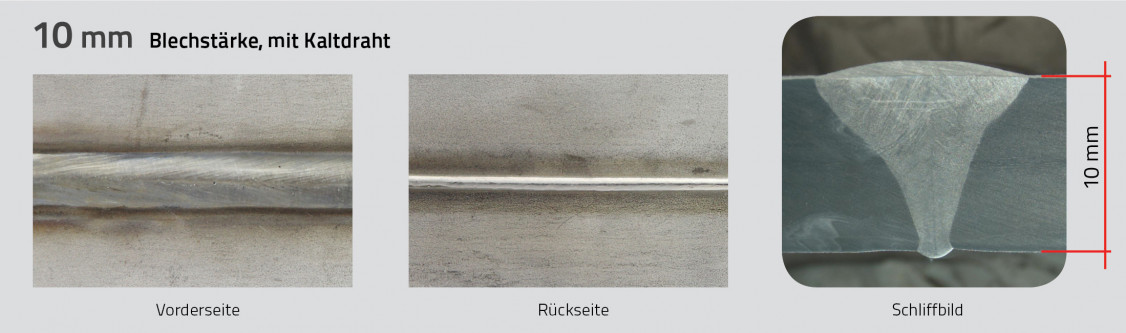

Example of use 2: Single-layer joint welding

Thin sheet metal can be welded with forceTig® without any additional filler materials. The concentrated arc output results in high welding speeds without compromising on the usual great seam quality. Welders can weld high-alloy metal plates with thicknesses up to ten millimetres in a single pass thanks to the high arc force and the large penetration depth of forceTig®. The increased energy density of the forceTig® arc results in minimal distortion and less discolouration and prevents the need for post-weld work.

Weld efficiently with future technology

The advantages of the innovative forceTig® process are more obvious when it comes to working with technically challenging high-alloy materials. Hydrogen is liquid and stored under extremely low temperatures, meaning weld seams need to be 100 per cent tight, even with high loads. These high technological and mechanical demands, especially at extremely low temperatures, are no problem for forceTig®. The optimised process also means there is no need for weld seam preparation, resulting in significant time savings, increased efficiency and improved productivity.

forceTig® – ideal for a wide range of applications

forceTig® can be applied to automated systems where high-quality weld seams and high welding speeds are needed. The focussed arc means reduced heat input which, in turn, reduces distortion and prevents the need for post-weld work. The process is user-friendly with just a few parameter settings and an easy-to-change electrode.

(Source: EWM Press Release)