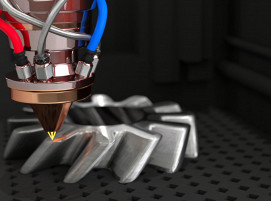

3D-Printer for Micro Applications

Nano Dimension, a supplier of Additively Manufactured Electronics (AME) and multi-dimensional polymer, metal & ceramic Additive Manufacturing (AM) 3D-printing solutions, announced the launch of its Exa 250vx Digital Light Processing (DLP) 3D Printer for micro applications.

Developed to enable the creation of notable resolution micro parts at high production throughput, the high-speed Exa was unveiled at Formnext in Frankfurt, Germany, in November. Designed using insights gathered from users of Nano Dimension’s established Fabrica Tera and Fabrica Giga systems, the Exa 250vx has been engineered to deliver high productivity in the industry for precise micro parts. Built to support the demands of service bureaus and OEMs (Original Equipment Manufacturer) alike, the Exa 250vx Micro 3D-printer provides a reliable and cost-effective alternative to traditional micro-manufacturing methods, including micro-injection molding and micro-CNC.

“Manufacturers producing micro parts are facing a trade-off between precision and productivity,” says Nir Sade, Senior Vice President of Additive Manufacturing at Nano Dimension. “As part of Exa’s development, we worked closely with customers to address a host of needs such as high-volume parts production with micro level detail for parts larger than the 50 mm build limit we currently have on the Tera. The result is a system that provides the perfect balance of quality, productivity and cost, making it a game changer for the industry.”

With its larger 100 mm × 100 mm × 70 mm build volume, 7.6µm XY resolution and layer thickness of just 10 microns, the Exa combines sought after attributes that deliver rapid production and high resolution, allowing manufacturers to produce the specific micro parts to meet their particular engineering requirements.

(Source: Nano Dimension Press Release)