Welding Steel Components More Efficiently with Thick Wire

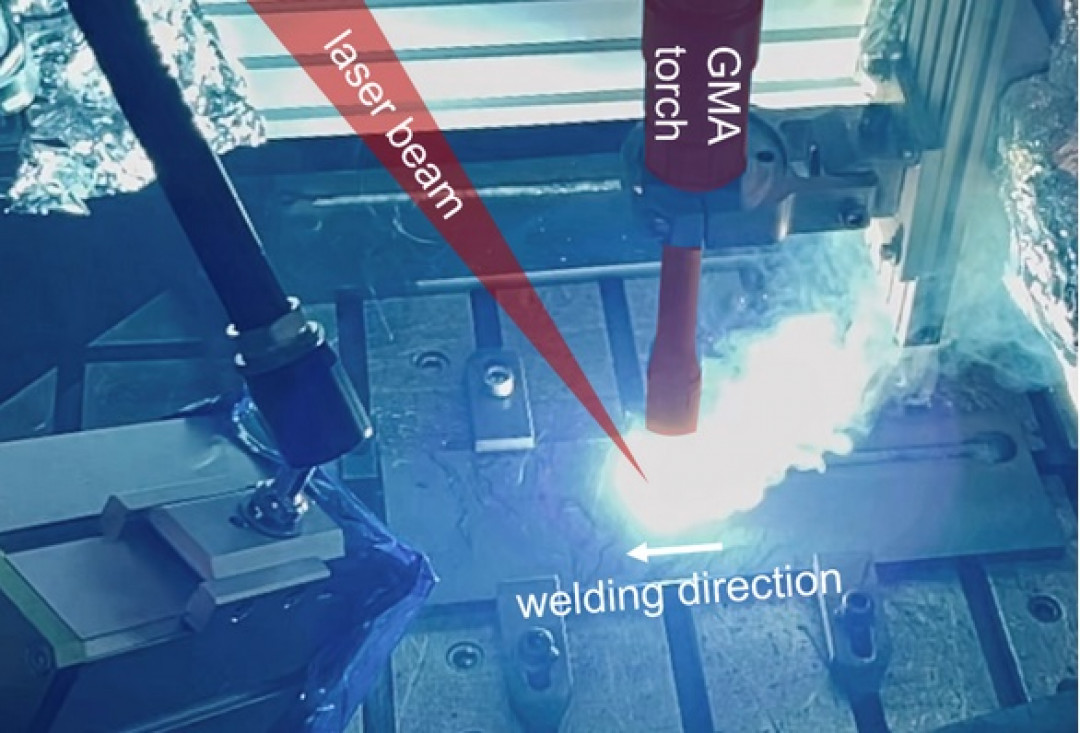

When welding thick sheets, large seam gaps must be bridged. Researchers of the "ÖkoHybrid" project want to enable closing the gaps with fewer layers, by feeding in a relatively thick wire with a diameter of 3 mm. This should make the joining process significantly faster and more resource efficient. An additional laser beam was used to accelerate and stabilize the process.

Stable hybrid welding process thanks to high-performance welding power source.

As part of the "ÖkoHybrid" project, the LZH scientists are investigating welding processes on fine-grain structural steels with sheet thicknesses of up to 20 mm. To this end, they will develop and build a new type of hybrid processing head. They want to combine a commercially available laser beam source with an output of 3 kW and a welding power source with an output of up to 40 kW. The welding power source is being developed by project partner ELMA-Tech. The project partner Förster Welding Systems will realize a complete system for the hybrid welding process. The Westsächsische Hochschule Zwickau will carry out fundamental investigations into the MSG welding process and also test and characterize the welded joints.

Hybrid laser arc welding combines the advantages of gas metal arc welding (GMAW) of thick wire with those of laser beam welding in a common process zone. The combined processes achieve a high deposition rate and a high welding speed. The use of 3 mm thick wires allows a large amount of material to be inserted, significantly reducing the number of layers to be welded and thus increasing efficiency. The additional laser beam increases the process stability.

Steel components in the heavy sheet sector: high demand for fast processes

Fine-grained structural steels are used in e. g. ship, vehicle and pipeline construction. They have a higher strength than conventional structural steels, which is why lower material thicknesses can be used. This allows for less material to be used and consequently reduces the weight of the components. However, the material requires high demands on the welding process: for example, cooling too slowly during the welding process leads to insufficient strength and toughness. If it cools too quickly on the other hand, cracks and seams with high hardness can form. The scientists therefore want to increase the welding speed and deposition rate while maintaining the required cooling times.

About ÖkoHybrid

The sub-project "Process development for laser beam MIG hybrid welding with larger wire diameters" is funded by the Federal Ministry for Economic Affairs and Climate Action (grant no. KK5111716KT3) as part of the project "Economical high-performance welding of fine-grain structural steels using laser MSG hybrid welding of larger wire diameters (ÖkoHybrid)" within the framework of the "Central Innovation Programme for SMEs (ZIM)".

(Source: LZH – Laser Zentrum Hannover Press Release)