ESAB’s “Ultimate Line-up” – So many ways to improve Welding and Cutting Performance

Fabrication shops across Europe are upgrading their fleets to inverter technology machines that meet EU Ecodesign Directives to improve energy efficiency and lower utility bills. With ESAB’s new “Ultimate Line-Up” of welding and cutting equipment – which features state-of-the-art digital technology – fabricators also gain advanced functions. ESAB showcased the Ultimate Line-Up at the Schweissen & Schneiden trade fare. The improved arc performance, productivity and quality attracted positive reviews from metal workers in every segment, as the Ultimate Line-Up features MIG, MMA, TIG, multi-process and manual plasma cutting equipment.

ESAB Rustler™ Industrial Series

The ESAB Rustler series of MIG welders features four models that combine simple, intuitive controls, reliable operation and welding outputs of 280A or 350A at 40% duty cycle. All Rustler machines use a premium 4-wheel drive feeding mechanism to deliver precision arc starts and stops and steady feeding with wire diameters from 0.6 to 1.6 mm. Fabricators will enjoy stable arc and minimal spatter to further improve productivity on thin to thick metal. Rustler also offer an MMA (SMAW) output, and the Rustler EM 350C PRO Synergic also provides a 350A output and adds the benefits of synergy control, which saves set-up time, promotes consistency and helps less experienced welders produce optimal welds.

Renegade™ VOLT for Ultimate Portability

The Renegade VOLT ES 200i revolutionizes the industry as the first-ever interchangeable battery-powered welder. It allows users to accomplish jobs in difficult-to-reach locations, locations without power, and applications where portability and quick set-up provide operational efficiencies. Depleted batteries can be swapped for fresh batteries in seconds, so users can continue welding without interruption. The machine weighs 23 kg with the batteries and battery box and 10 kg when the box is detached.

Powered by four DEWALT® FLEXVOLT® 12 Ah (amp-hour) batteries, Renegade VOLT offers an MMA output of 10 – 130A and TIG output of 10 –150 on battery power. Renegade VOLT also connects to 120V/230V AC mains power and provides a maximum welding output of 200A when connected to 230V mains. Additionally, Renegade VOLT has an exclusive AMP + Hybrid Mode that supplements mains power with battery power to mitigate nuisance circuit breaker tripping.

Renegade Single-phase MMA and TIG Welders

The Renegade series of single-phase welders includes the Renegade ES 210i inverter for MMA and Live TIG welding and the Renegade ET 180iP, ET 210iP and ET 210iP Advanced inverters for pulsed TIG welding with high frequency (HF) TIG arc starts. These units offer an industry-leading combination of premium arc performance, power, portability, and full-feature controls. They use 1Ph, 115/230V AC mains power and feature maximum welding outputs of 180 and 210 amps, respectively, at 25% duty-cycle. The Renegade ET 210iP Advanced features a 110 mm-wide TFT LCD color display that, in combination with two soft keys and a push-button knob, provide intuitive and easy access to all welding functions.

ESAB Rogue Light Industrial Series

The ESAB Rogue EM and Rogue EMP are a series of easy-to-use, compact and lightweight welders. Rogue welders build on the Rogue brand promise of an unbeatable combination of performance, power and price. With 180- and 210-amp models available, Rogue meets the diverse needs of professionals, hobbyists and first-time welders with a broad portfolio of feature-rich-yet-affordable machines. All Rogue EM and EMP inverters feature Arc Dynamics, a control to fine tune arc characterics for a crisp/stiff arc when welding carbon steel or a smooth/soft arc when welding stainless steel.

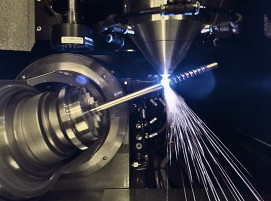

Cutmaster+ Manual Plasma Family

Building on the success of the Cutmaster 30+ introduced last year (recommended pierce and cut capacity of 6 mm), ESAB has launched the Cutmaster 50+ (recommended pierce and cut capacity of 16 mm) and Cutmaster 70+ (recommended pierce and cut capacity of 19 mm). The Cutmaster+ family features ESAB’s signature 110 mm TFT LCD display, which is paired with a glove-friendly knob for selecting and setting parameters. The Cutmaster 50+ and 70+ each weigh 16 kg, use 400V 3ph mains power and come with an SL60 1Torch™ with a 5.0 m cable.

The Cutmaster+ machines also offer a built-in 14-pin CPC port for easy CNC mechanization. This gives smaller fabricators the flexibility to switch between manual and mechanized cutting to maximize utilization of their machines. Pair with the ESAB MechPak for straight line cutting and gouging applications.

Sentinel A60 and A60 Air Helmets

The new Sentinel A60 offers a 40 percent larger viewing area that measures 4.65 x 2.80 in., an optical quality rating of 1/1/1/1 for a distortion-free view and ESAB’s new OpTCS™ broad-spectrum light control technology and True Color view for a clearer distinction between the arc, the weld puddle and heat-affected zone. Sentinel A60 also adjusts shade in half-point increments from shade 5 to 13. Sentinel A60 air connects seamlessly to the EPR-X1 PAPR unit to provide advanced respiratory protection from harmful welding fume particulates. The EPR-X1 offers a robust, compact housing with a powerful blower to ensure maximum life and performance.

For more information, visit esab.com or go directly to the ESAB Ultimate Line-Up site.

(Source: Press Release ob ESAB)

Schlagworte

CuttingInverter TechnologyTig weldingWelding