MicroStep Europa Celebrates Launch of CompetenceCenter South

"Today is a very special day for us," said Johannes Ried, Managing Director of MicroStep Europa GmbH, in his welcoming speech at the official ceremony. "With the opening of our new technology and logistics center, we are celebrating another milestone together with friends, customers, partners and family. Right across from our company headquarters, we have created an incomparable center for cutting, automation, edging, deburring and more." The entire site covers 3,700 m² including offices (800 m²), logistics center (1,500 m² warehouse space) and showroom (1,350 m²).

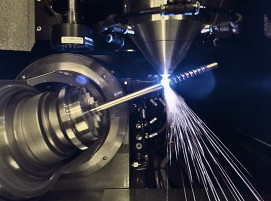

More than 600 visitors from politics, business and craft took the opportunity to be inspired by the technological range and to celebrate with MicroStep Europa. There was plenty to experience at the machine shows: for example, 3D processing using a plasma rotator and oxyfuel rotator on the MG series. Or the WaterCut, which demonstrated the power of water. The MSF Pro laser all-rounder also demonstrated its versatility with the rotator. Bending precision was presented on the Euromaster press brake as well as innovative deburring systems for surface processing. The MSE SmartFL laser cutting system was also showcased. “This smart fiber laser is the first IndustryFusion ready system. It meets all Industry 4.0 requirements, which opens up a wide range of benefits for efficient production," explained Fabio Oettl, CEO of the IndustryFusion Foundation, at the presentation of the revolutionary IndustryFusion digitalization solution.

Around 20 technology partners also presented additional systems and solutions in the complementing trade exhibition. The program was rounded off by expert presentations – for example on the topic of automation & digitalization or weld seam preparation on a wide variety of materials and geometric shapes. "The response to our Technology Days was overwhelming. The new premises with office complex, logistics center and showroom met with enormous interest. For us, this was once again a strong signal of how much power there is in our network," summarized Igor Mikulina, also Managing Director and company founder.

Following demonstrations, presentations and an exhibition, the new CompetenceCenter was officially opened with a festive ceremony featuring a diverse program of acrobatic shows and musical entertainment. “It was a great event. Everything was perfectly organized. The demonstrations were informative, also regarding the partner companies. It was an all-round successful event from start to finish. I'd be happy to come again any time,” said Ludwig Lertinant from Kraftanlagen München GmbH, Production Manager at the Haiming site.

The Technology Days marked the end of an intensive construction phase. The demonstration center was commissioned in 2023, and the logistics center was completed and occupied at the turn of the year. In total, MicroStep Europa invested more than € 6 million. The following systems are permanently in operation at this location: The latest generation of plasma, laser, oxyfuel and waterjet technology in 2D and 3D, state-of-the-art bending solutions from the MicroStep Industry powered by Accurl brand as well as small and large deburring solutions for surface processing.

Save the date: Technology Days 2025

MicroStep Europa will also be hosting the Technology Days next year on June 26 and 27, 2025. We will keep you posted.

(Source: MicroStep Europa GmbH Press Release)

Schlagworte

AutomationCuttingDeburringMaterial ProcessingMetal Processing