Strohm installs 33 km corrosion free pipes

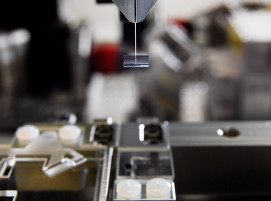

The global thermoplastic composite pipe (TCP) company, has been awarded a contract to supply 33 km of its TCP flowline for Aramco’s Fadhili gas plant in Saudi Arabia. This is Strohm’s first commercial contract for onshore application in the region. The project also marks the first time the company uses its newly offered electrofusion coupler (EFC), a completely non-metallic, welded and fully bonded joint that is corrosion free and enables buried application as it requires no seals.

The six-inch glass fibre polyethylene composite pipe will be produced in the company’s manufacturing plant in the Netherlands and assembled in the field using local workforce. The low weight solid pipe structure is immune to corrosion and has a smooth liner ensuring enhanced flow.

The contract was awarded following Aramco’s and its engineering partner KBR’s material selection studies, which showed that TCP was the most suitable solution for the flowline, due to its demonstrated fluid compatibility, high qualification standards, lack of corrosion and low carbon footprint.

Strohm’s Vice President for Africa, Middle East & Asia-Pacific, Fabienne Ellington, said: “This contract represents a significant milestone for Strohm, and it is a testament to our longstanding relationship with Saudi Aramco and the company’s trust in our products. The award reinforces our commitment to Saudi Arabia as a strategic growth area and its role as a pivotal gateway to the broader markets in Middle East, Asia and East Africa.

This will be a stepping stone as we aim to expand our reach and deliver value across these dynamic geographies. Not only that, but the EFC’s adoption also enhances our onshore operations and positions us at the forefront of innovation, paving the way for our entry into the hydrogen and carbon capture and storage markets in the region and globally.”

(Source: Strohm B. V.)

Schlagworte

BondingElectrofusionOnshorePipesTCPThermoplasticWelding