Underwater Weld Repairs - Requirements and Execution, Part 3

The following 3 case studies describe briefly three types of underwater wet weld repairs performed on different assets over time periods ranging from 6 port stops to 5 years.

Underwater wet weld repair – build-up welding

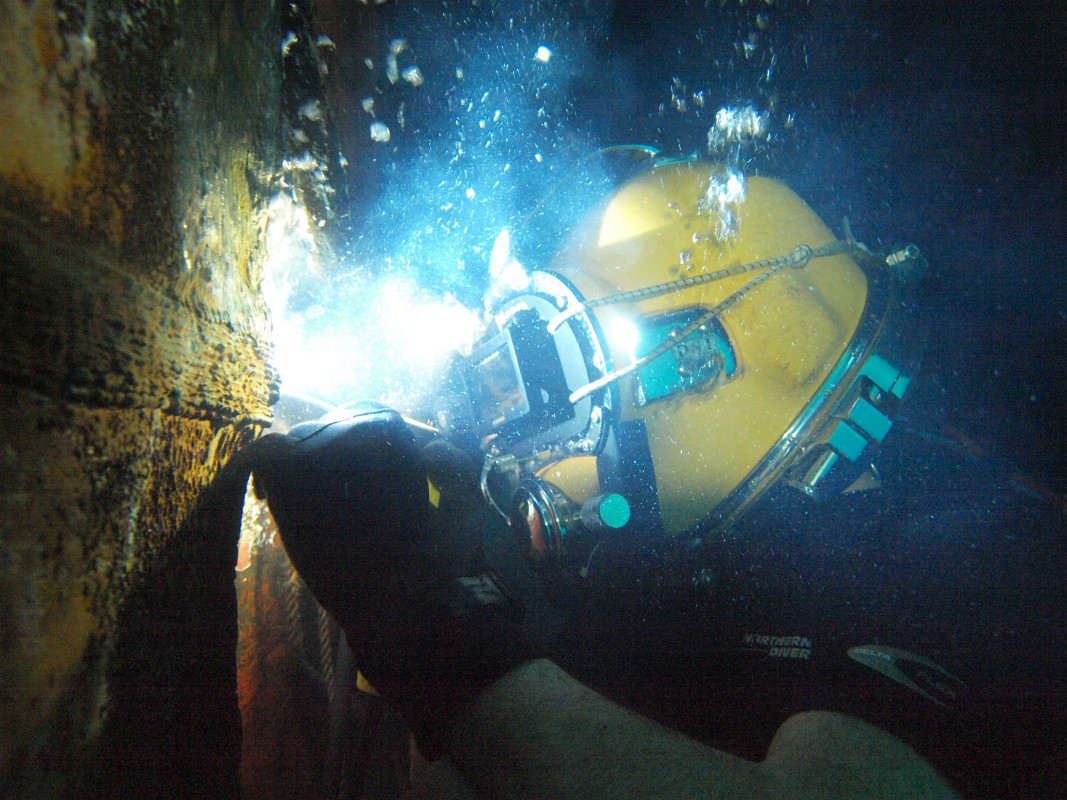

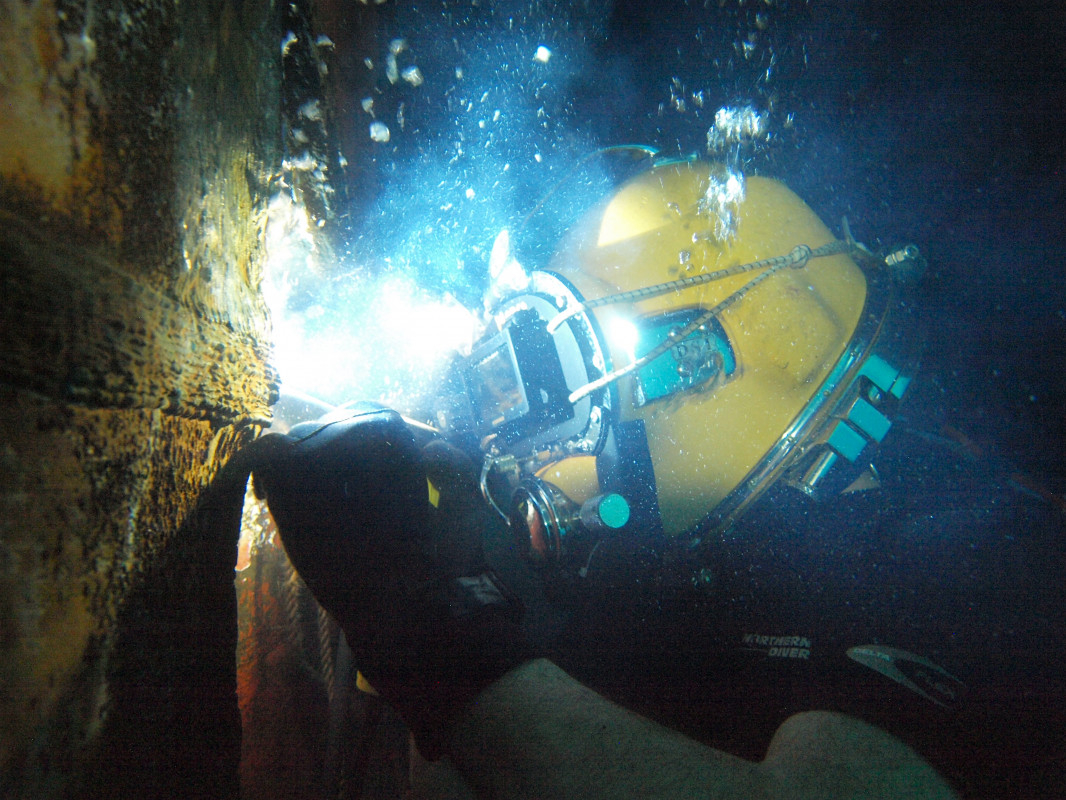

An inspection dive performed on the two rudders of a 290 m long cruise ship with a gross tonnage of 113,323 t revealed heavy cavitation and erosion damage on both the port and the starboard side rudders. When the damage, caused by galvanic corrosion was discovered, the ship was out of dry dock for approx. 3 months. Corrosion was observed in several areas on both rudders, ranging from mild corrosion to 100% section loss. The repair was performed by cropping wasted sections, and by build-up welding using underwater wet welding techniques. In addition, the starboard side rudder was filled with water and had to be de-watered after the repair.

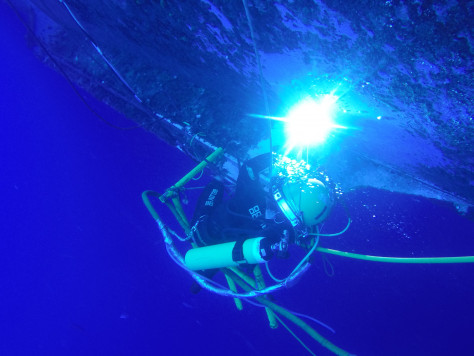

SGS together with the cruise line and the classification society developed a repair plan involving the qualification of underwater wet welded groove weld procedures to the class A requirements of AWS D3.6. In addition to the groove weld procedures welded in the flat, horizontal and vertical position, we also had to qualify “build-up welding”. Together with class, we decided on a plate with a machined “gap” to be filled with weld metal, to simulate building up wasted material to the original material thickness. Those test plates had to be welded in the vertical and the horizontal position. The welding of one “build-up” welding test plates took approx. 16 hours. Over a period of three months an SGS crew sailed with the vessel. During regular port stops divers were deployed to restore the wasted material to its original plate thickness. The final repair was considered permanent and was performed without interrupting the itinerary of the vessel.

Underwater wet weld repairs – skeg replacement

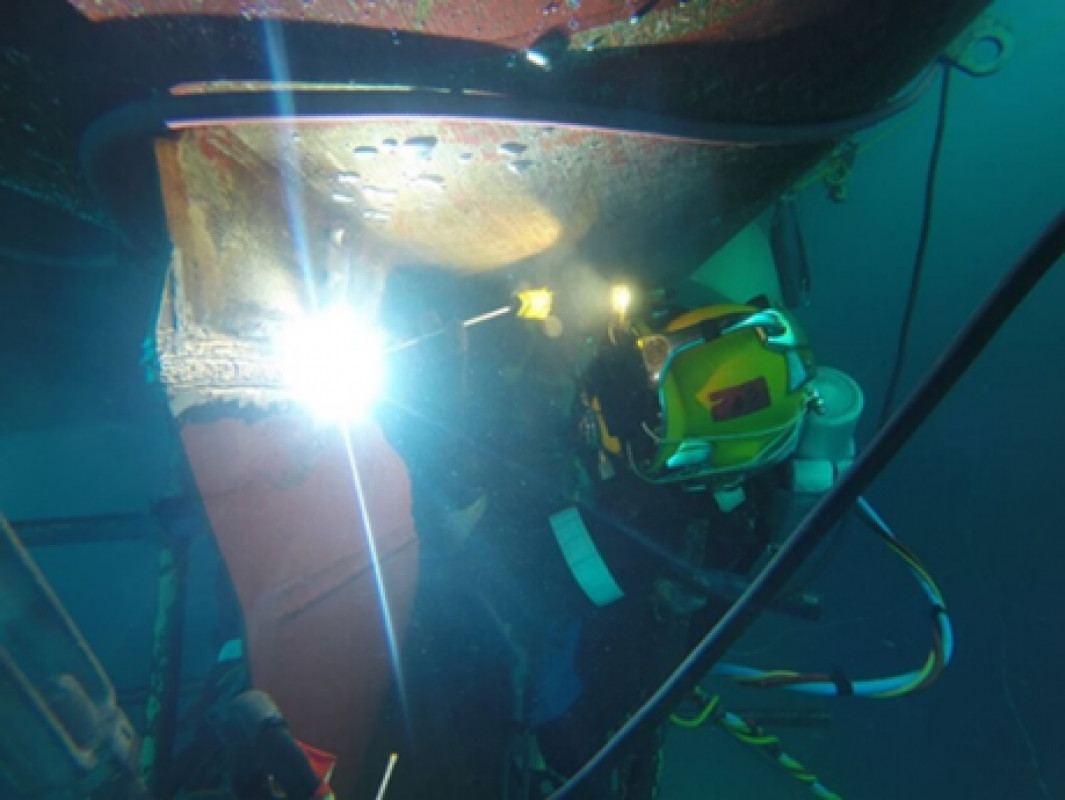

During a night grounding the skeg of a 325 m long cruise ship with a gross tonnage of 145,655t, was ripped off from the starboard azimuth thruster, a marine propulsion unit consisting of a fixed pitch propeller mounted on a steerable gondola ("pod") containing the electric motor driving the propeller, allowing ships to be more maneuverable. SGS worked together with the Original Equipment Manufacturer (OEM) and the Cruise Line to install a new skeg.

A new skeg was manufactured by the OEM and welded with a complete joint penetration (CJP) weld by SGS welder divers to the bulkhead on the bottom of the housing of the thruster, employing underwater wet welding techniques.

SGS welder divers sailed with the vessel and the repairs were performed during regular port stops, without interrupting the itinerary of the vessel.

Underwater wet weld repair – bilge keel repair

During the conversation from a tanker to a floating production storage and offloading (FPSO) unit, the bilge keel of the former very large crude carrier (VLCC) with a length 274 meter and a gross tonnage of 132,361 t was modified. The modification consisted of an increase in bilge keel width from 600 mm to 1,200 mm and an increase in length from 102 m to 165 m. A bilge keel is a nautical device to reduce the rolling motion of a ship. Design flaws together with poor workmanship caused the bilge keel to fracture during operation in several locations.

SGS worked together with the owner and the classification society to perform permanent underwater wet weld repairs on the fractures, without interrupting production. A total of 30 High Priority Repairs (number 1 priorities) on the PORT and STBD side were identified and re-quired underwater wet weld repairs. In addition to the number 1 priorities, two number 2 priorities and 120 number 3 priorities, consisting of 120 welds, to seal faying surfaces were identified. Number 3 priority welds were not structural and served only sealing purposes. A “priority” was identified as a “location” on the bilge keel that would require repair on one or multiple fractures. The type of priority (1, 2, or 3) was determined by the builder of the FPSO, the owner, class and SGS.

The priorities for the sequence of the repairs were based on discussions among the builder, the owner, and SGS. The most influential factor in determining the sequence of the repairs was the criticality of the damage. A critical damage was defined as:

- Crack growth rate.

- What were the consequences if failure of the part occurred?

- Location of the damage on the bilge keel.

The underwater wet weld repair of the bilge keel of the FPSO started at the end of 2015 and was completed in April 2021. This was the first time that a repair of this magnitude was successfully completed by employing underwater wet welding techniques with the approval of a classification society. After completion, all welds were subject to visual and magnetic particle inspection. In addition to the final inspection after completion of each repair, the 5 oldest repairs were selected (three on the PORT side and two on the STBD side) for additional visual and magnetic particle inspection. When the additional NDE was performed, the selected repairs were in service between 1075 and 1492 days, exposed to high hydrodynamic forces. No rejectable indications were observed. All reported fractures were repaired and subject to visual and magnetic particle inspection and received final approval from the American Bureau of Shipping (ABS) and the Brazilian NAVY.

Summery

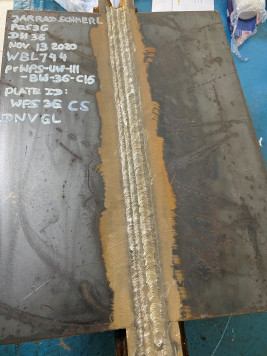

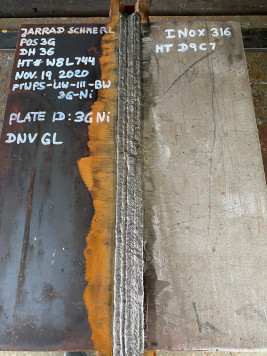

With the introduction of specially designed underwater welding electrodes, improved techniques and better training, permanent repairs can be achieved using hyperbaric wet welding. As mentioned earlier in this paper, underwater wet welds comparable to their top site welded counterparts regarding mechanical properties and meeting NDE requirements can be produced. The following photographs show welding procedure qualification plates welded on different type of materials and at different water depth to emphasis the quality of underwater wet welds that can be achieved.

References

[1] “Wettbewerbsfähige Lösungen für die Fügetechnik: DVS-Aktuell: Unterwassertechnik“, DVS – Deutscher Verband für Schweißen und verwandte Verfahren e.V.

[2] Wikipedia

[3] “Underwater Welding Code”, AWS D3.6M, American Welding Society

[4] “Underwater welding technology: Fundamentals, research and applications”, Dr.-Ing. Peter Szelagowski, DVS Media

[5] Hydroweld Training Booklet

[6] Underwater Repair Technology, John H. Nixon, Gulf Publishing Company

Authors

Uwe Aschemeier, SGS Subsea Global Solutions, Miami FL, USA

Kevin Peters, SGS Subsea Global Solutions, Miami FL, USA

Schlagworte

Hyperbarics Dry WeldingHyperbarics Wet WeldingUnderwater Welding