Intelligent Robot Assistance Systems Improve Weld Quality

WireSense, TouchSense, SeamTracking and TeachMode are patented assistance systems for robotic welding designed by Fronius to improve weld quality and increase efficiency in industrial manufacturing. The welding wire acts as a sensor for the robot and simplifies welding path programming or detects deviations in the component position as well as air gaps over the course of the seam. Using this data, the robot can then correct the weld path – adjusting it based on the identified position points.

In spite of advanced robot technology and almost seamlessly interconnected systems, inaccuracies and deviations repeatedly occur in industrial production. In some cases, minimal material differences or imprecise clamping devices can have a negative influence on the welding result and potentially cause time-consuming rework, costly component rejects, or huge cycle time losses. Integrators often resort to using optical measuring systems to avoid having to make time-intensive manual readjustments. Fronius has developed high-tech solutions for the intelligent iWave, TPS/i and TPS/i TWIN welding systems that require neither a camera nor manual readjustment.

The TouchSense assistance system has been specially developed for fillet welds. Before each weld, the robot automatically touches the sheets being joined at the start and end of the weld. Whether it is the wire electrode or gas nozzle making contact: the signal is always clearly assigned and correctly transferred. The low sensor voltage creates a short circuit when the torch touches the workpiece, which enables the robot to precisely determine the weld position and adjust the welding parameters dynamically.

WireSense – precision thanks to CMT technology

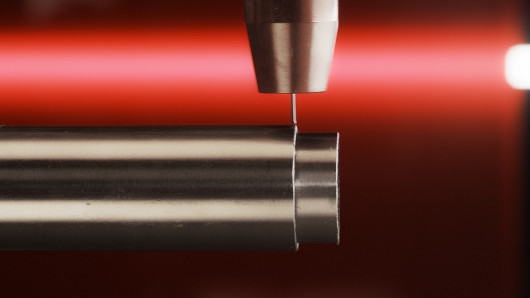

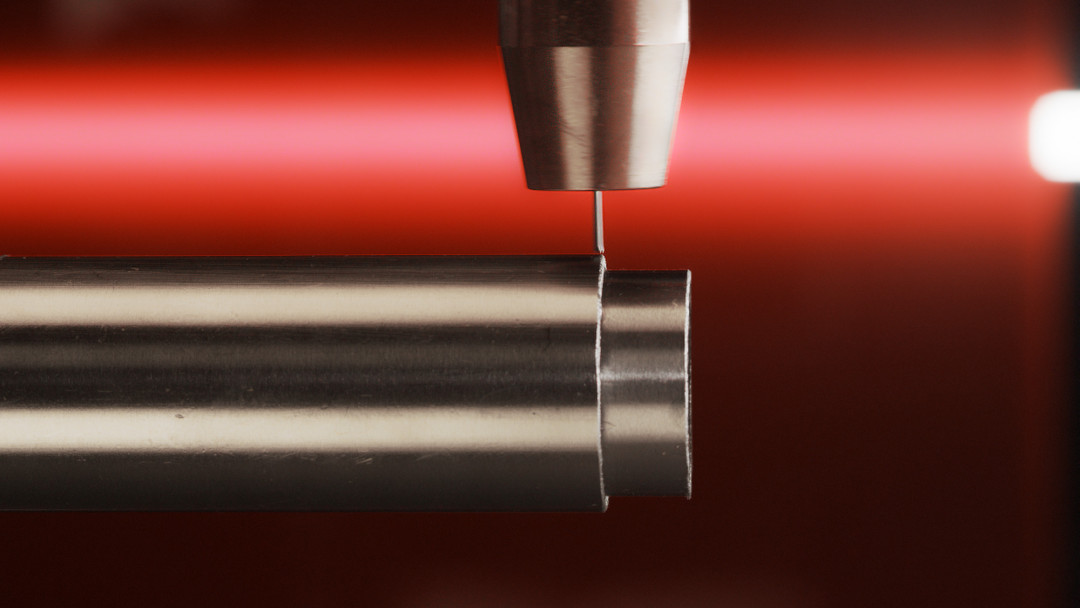

“Adding special controller software to our highly sensitive and dynamic CMT drive turns the welding wire into a sensor that can identify contours or air gap deviations on the component,” reports Philipp Schlor, Strategic Product Manager, Industrial Welding Solutions, at Fronius International. To ensure precision control of the welding wire, the Fronius welding system simply needs to be equipped with a CMT-ready system. The Welding Package, i.e., the CMT (Cold Metal Transfer) welding process itself, is not required.

CMT-ready systems consist of a wirefeeder on a wire drum or wire spool, a wire buffer and a CMT Robacta Drive, in other words a second wirefeeder on the torch itself. A reversing wire movement, which takes place at around 100 Hz, causes the electric motor in the drive unit to scan the metal surface with the wire. This high-frequency scanning of the workpiece provides the necessary precision. Even if the scanned surface is uneven the edge can still be detected and measured.

Detecting the edge position and air gap height

Every raising and lowering operation on the component can be recorded accurately relative to a reference point specified at the start of the scanning process. In seconds the robot has compared the taught positions with those measured, or in other words, it has checked the stored values against the actual position data. If it detects any differences, the course of the seam is adjusted accordingly in the robot’s coordinate system and the weld is produced in the right place.

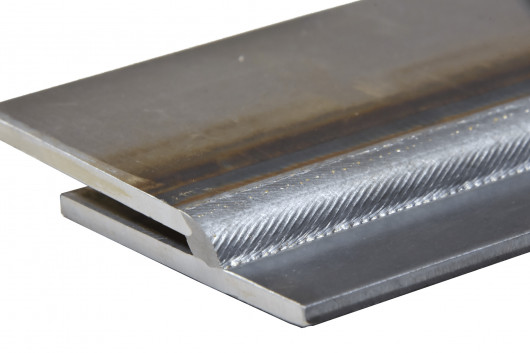

Bridging air gaps

With WireSense the wire electrode becomes a height sensor, allowing air gaps to be determined on lap joints using the precisely measured sheet edge height. To achieve perfect results it is possible to specify in advance which jobs stored on the Fronius welding system should be called up for different air gap sizes. This allows the robot to always respond appropriately and weld with welding parameters that are ideal for the air gap dimension in question.

Program robots up to 30 per cent faster

The key to high quality lies in teaching the correct welding path. The tried-and-tested TeachMode assistance system helps the welder set the weld seam positions on the robot, making the programming process easy. The reversing wire movement prevents the wire from bending in the event of contact with the component.

SeamTracking: seam tracking during welding

When thick sheets or long seams are being welded, the heat input can lead to component distortion. To ensure the robot still welds in the right location, a reliable system is needed which detects the welding position during welding, such as on a fillet weld or prepared butt weld. To do so, the robot moves back and forth between the two sheets during welding. The controller converts the actual values identified into signals for the robot controller. The robot then uses these signals to identify the specified welding position – or possible deviations – and corrects the path automatically.

(Source: Fronius International GmbH Press Release)

Schlagworte

RobotRobotic WeldingRobotsTeachingWeld SeamWeldingWelding Seam