METAL SHOW & TIB 2025 will take place in Romania's largest exhibition hall

From May 13th to 16th, the entire metal processing industry, along with equipment and technology sectors, will gather at METAL SHOW & TIB 2025, held in Romania's largest exhibition hall – ROMEXPO. For four days, specialists can see and test the latest technologies, equipment, and industry solutions, tailored to current demands.

Why participate in the largest technical trade fair in Southeast Europe, visited annually by thousands of decision-makers:

- Over 13,000 sqm of exhibition space

- More than 160 confirmed companies – suppliers and market leaders setting industry direction

- Over 20 % of exhibitors are first-time participants – new business opportunities

- Major international players return in force – Amada, Fanuc, Hoffmann, Iscar, Kemppi, Klingspor, Mitutoyo, Okuma, Trumpf, Universal Robots, and many others.

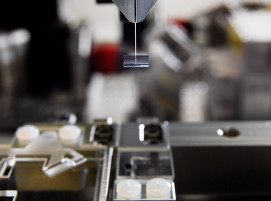

- Focus on key industries – Sheet metal processing, cutting, welding, automation, and robotics

- Live demonstrations and cutting-edge technologies – See equipment in action that can grow your business

- Valuable networking – Thousands of decision-makers, the exact target audience you need

For companies looking to strengthen their market presence and promote their products and services, METAL SHOW & TIB 2025 is the ideal platform. From innovative startups to established companies, this fair offers all participants the opportunity to showcase their offerings and engage directly with potential clients and business partners.

You can find further information here:

(Source: Euroexpo)

Schlagworte

AutomationCuttingExhibitionIndustryInternationalMetalMetal ProcessingRoboticsTechnologyWelding