You will find the company at the fair in Hall 4, Stand 4F38.

You will find the company at the fair in Hall 4, Stand 4F38.

![SCHWEISSEN & SCHNEIDEN 2023 [EN]](/images/frontend/journals/dvs-sus_sm.png)

MX3D presents Wire Arc 3D Welding Technology

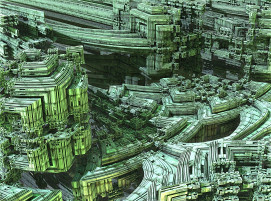

MX3D is widely recognized as a key pioneer in the robotic wire arc additive manufacturing (WAAM) industry. As one of the market leaders in welding-based 3D printing technology, WAAM technology extends the benefits of 3D printing to be applied to particularly large metal components. Weld seam after weld seam is placed on top of one another under robot control, producing ever larger and more complex components.

The growing interest in the WAAM technology spans many industries. MX3D continues to demonstrate the geometric capabilities of the technology as well as its mechanical properties with new use cases. The mechanical properties of 3D printed metal are equal and even, in most cases, surpass cast or ingot milled materials. Thus, all weldable metals can be used for the WAAM process. Common materials include various alloys of stainless steels, aluminum, copper- or nickel-based alloys. For the energy giant Engie, MX3D welded a 350 kg bronze-aluminum impeller - pure printing time 9 days. The 1 m diameter component will be on live display at the MX3D booth at SCHWEISSEN & SCHNEIDEN. For the entire metal processing industry with large components, the WAAM process offers enormous potential to produce decentralized and complex geometries without large material waste. Custom flanges or tooling shapes that are expensive to cast can now be 3D printed in consistent quality.

MX3D is the first company to develop WAAM-specific software to incorporate all welding and robotic parameters. The MetalXL software solution, as well as the production system the M1 Metal AM system, have been very popular with WAAM users since their launch - and can be used independently of their welding machines. The integrated sensor systems enable high print quality and consistency, they record the process parameters and are used for optimum temperature control. The consistent process data base means that all print parameters are directly logged for both in-house analysis and qualification purposes.

The Amsterdam based company MX3D has been developing robotic 3D metal printing technology since 2013 and gaining printing experience since then. The technology allows more flexibility and optimization on the design. It also saves on material, lead time and cost across a number of industries including maritime and construction. The company has become renowned for the 3D printed stainless steel bridge in the city center of Amsterdam. On 21-06-2023 a second bridge, named "the Solstice Bridge", was opened in Amsterdam.

(Source: MX3D)

Schlagworte

Additive ManufacturingSCHWEISSEN & SCHNEIDEN 2023Software