Oil-free High-tech Lubricants Protect the Environment and Alleviate Cost Pressure

The medium-sized lubricant expert LBI oil free is setting new standards in the metalworking industry with its broad portfolio of oil-free high-tech lubricants. The outstanding advantages, above all the significant cost savings and the contribution to environmental protection, make the products from LBI oil free a forward-looking alterna-tive. The various solutions make a significant contribution to increasing efficiency in production and send a strong signal in favour of sustainable and environmentally friendly processes in the metal-working industry.

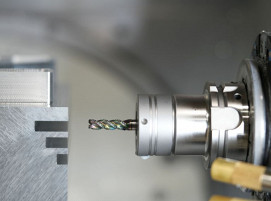

In times of unbroken price wars, particularly in the automotive industry, in the manufacture of white goods and in furniture production, cost savings and efficiency, but also environmental protection, are decisive factors when purchasing lubricants. This is where LBI oil free scores with its innovative lubricant portfolio, which not only takes ecological aspects into account, but also enables significant cost benefits and time savings in production. The oil-free lubricants from LBI oil free are used in the machining of steel, high-strength steels, stainless steels and aluminium. The products are particularly effective in deep drawing and punching as well as tube bending and drilling. Minimum quantity lubrication, mandrel lubrication systems or manual application not only minimise consumption, but also increase the service life of the machines. Lub-ricants can now also be printed with pinpoint accuracy.

A decisive advantage is the speed with which the workpieces dry after application of the oil-free lubricants. This enables direct further processing without time-consuming washing. Even welding and painting are possible without any problems. This factor not only saves costs for the time-consuming cleaning of workpieces and machines, but also reduces the burden on the environment caused by the expensive disposal of waste water in hazardous waste.

The company's lubricants and anti sputter fluids are based on regenerative and synthetic polymers that are biodegradable, label-free and free of chlorine, silicone and heavy metals. This not only complies with the EU REACH directives, but also emphasises LBI oil free's commitment to sustainable and environmentally friendly production processes. LBI oil free's dispensing technology enables precise application of the sustainable lubricants, which not only streamlines work processes. It also protects the health of employees by creating a less stressful working environment.

(Source: LBI Press Release)

Schlagworte

AluminiumEnvironmental ProtectionIndustryMetalPolymersSteelSustainability