You will find the company at the fair in Hall , Stand .

You will find the company at the fair in Hall , Stand .

![SCHWEISSEN & SCHNEIDEN 2023 [EN]](/images/frontend/journals/dvs-sus_sm.png)

Worry-free welding: Well-thought-out concepts for every need

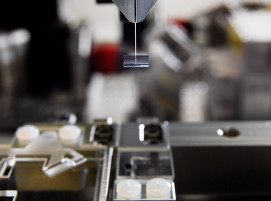

At the SCHWEISSEN & SCHNEIDEN fair EWM will be exhibiting as a full-range provider. The company will be presenting state-of-the-art welding technology for manual welding, cobots and robot welding cells, as well as other automation solutions.

Whether it’s welding machines, welding torches or welding wire, manual welding, robot welding or full automation – for over 65 years, EWM have not only been engaged in the production of welding machines and corresponding accessories but have also established themselves as a full-range provider with a solution for every individual customer need. The specialists in arc welding technology are continually developing new components and systems, including in areas of digalitisation and automation. Efficient and reliable automation solutions ensure consistently high, reproducible product quality. Their cost-effective XQbot cobot welding cells with integrated CRX robot from Fanuc is an ideal entry-level solution to produce small and very small batches. This is comparable to an industrial robot regarding accuracy, precise repeatability & stability and ensures high weld seam quality.

Complete modular systems for automation which are based on standard components, yet are individually configurable, are also available to EWM customers. The company will also be presenting a well-thought-out robot solution for the forceTig welding process at the trade show. This joining process enables higher energy density in the weld pool by way of an extremely concentrated welding arc and makes maximum welding speeds possible. The introduction of automated welding processes has far-reaching implications for the complete production-process and can’t be looked at in isolation – it must be considered in conjunction with upstream and downstream processes.

EWM support their customers from the very beginning, offering comprehensive consultation through to commissioning and beyond. The experts conduct a detailed analysis of the actual situation, handle planning and concept creation, facilitate initial sample welding and offer comprehensive training. Customers benefit from comprehensive service. With the Xnet Welding 4.0 welding management system, EWM provide support across the entire value-creation chain. Intelligent data networking increases productivity. This enables improved organisation of production, planning, quality management, welding coordination personnel and management, reduces cost and significantly increases overall efficiency.

(Source: EWM GmbH)

Schlagworte

AutomationCobotsQuality ControlRobotsSCHWEISSEN & SCHNEIDEN 2023TorchWeldingWelding 4.0Wires